Factories in the Industrial Revolution

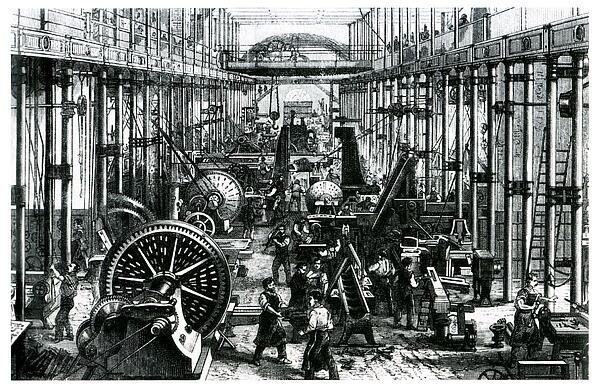

As the Industrial Revolution gained pace in the 19th century, the power of steam became more and more important. It allowed for the development of ever more efficient and powerful machines. Factories in the Industrial Revolution varied in size, from the small water-powered mills to large urban factories, each with their own chimney and steam engine. By 1870, over 100,000 steam engines were at work in Britain.

The development of the steam engine, as well as machinery such as the power loom, ended the domestic system of production. Factory owners could employ unskilled workers, leading to the mass production of cheaper goods and materials.

The desire to maximise profits meant that health and safety was all but ignored in factories. Working hours were long and conditions were often terrible. Young children and women were employed as cheap labour and given little training or safety provisions.

Naturally there were good and bad factory owners in terms of how they treated their employees. Richard Arkwright, the pioneer of the factory system, was regarded as one of the good ones. Although he had some tough rules in his factories - including fining workers if they whistled on the job or were caught staring out of the window) but he also did a lot of good things for them, such as building homes for employees, as well as establish churches and helping to educate child workers. Many owners would do no such thing.

Legislation was slowly introduced in the 19th century to improve working conditions in factories.The first of these was the 1833 Factory Act which banned children under the age of nine from working textile factories. Children aged nine to 13 could work a maximum of 48 hours a week, and 13 to 18 year-olds could work no more than 69 hours a week.

See also:

The Cotton Industry and the Industrial Revolution

MLA Citation/Reference

"Factories in the Industrial Revolution". HistoryLearning.com. 2026. Web.